- Detail

- Parameters

- Review

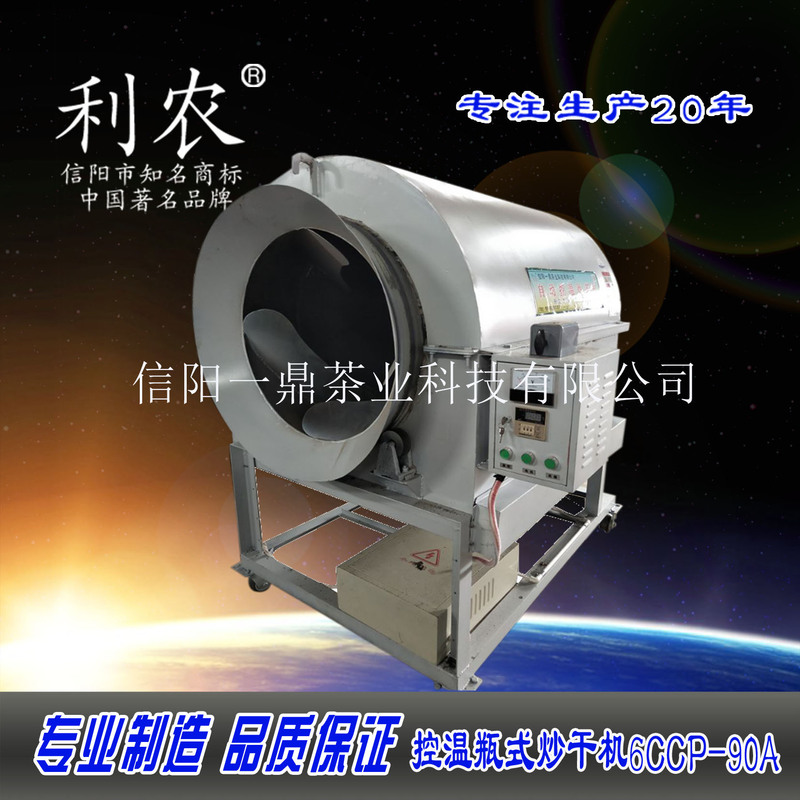

The latest automatic temperature-controlled bottle type frying machine, stainless steel wok.

1, the main features

A. Using automatic temperature control system, equipped with automatic temperature control electrical control device, accurate temperature control and convenient operation.

B. The thermal insulation material adopts special thermal insulation material to better prevent the heat from escaping, thereby achieving the purpose of rapid heating, clean and energy saving.

C. The rotating drum adopts advanced stepless speed regulation, the tea is fast and clean, the speed control operation is flexible and convenient, and the operation is stable, which is suitable for the frying of all kinds of tea.

D. Use the self-designed new heater to heat, high thermal efficiency, uniform temperature, brown and green fragrance.

2, the main components

It consists of main components such as frame, inner drum, outer cylinder, stepless speed regulating motor, gearbox and liquefied gas exhaust.

3. Operating procedures

1. Connect the machine to the three-phase four-wire 380V power supply, and connect the ground wire at the same time;

2, the machine must be placed horizontally, the base parts must not be empty;

3. Turn on the power, observe the machine voltage display table, and proceed to the next step after the voltage meets the requirements;

4. Press the motor switch button to test run. After no error, stop the machine.

5. Press the heating switch to set the temperature to the desired temperature value, start the main motor, and let the cylinder run;

6. When stopping, stop heating first, then cut off the power.

4, installation and maintenance

1. Regularly add the lubrication parts and tighten the fixing screws and bolts.

2. After the end of the tea season, check the gearbox oil quantity, fill or replace the oil;

3. For a period of time, the burner nozzle and the gas pipe should be descaled.

4. Check the wear and tightness of the drive belt.

5. When the tea machine is working, it should be filled with lubricating oil every day before turning.

5, safety precautions

A. This unit should be installed in a well-ventilated place.

B. The machine must be well grounded to ensure safety;

C. It is forbidden to directly pour water to rinse the surface of the frying machine and the inner barrel to prevent leakage caused by insulation failure;

D. It is forbidden to store or store flammable materials such as gasoline, alcohol, gunpowder and other flammable dangerous goods.

E. Do not use in places that are prone to water or in places with high humidity.

F. It is strictly forbidden to put your hand on the outer surface of the drum during mechanical operation to avoid burns.

6, the elimination of common faults

1, automatic shutdown; fuse (fuse)

1 Check if the fuse is blown, if it is blown, replace it;

2 Check if the external power supply is fully imported.

2. The number of revolutions does not reach the rated value; the voltage is too low, and the speedometer is adjusted to age.

3. If the fire is not found during the use of the product.

1. Press the ignition switch to check whether the ignition pin generates electric fire from the fire hole.

2. Check if the battery contact of the igniter is good or the voltage is too low, otherwise the battery No. 5 must be replaced.

3. Whether the ignition needle number is melted into a running position.

4. During use, the temperature rises or the temperature is out of control.

1. Check if the exhaust window is closed.

2. Check if the induction temperature probe passes through the insulation layer, otherwise it should pass through the insulation layer.

3. Check if the gas is turned on and the pressure is adjusted well (the clockwise direction is increased);

4. Check if the solenoid valve is working and the gas switch is open.

Dimensions(mm) | heating power(KW) | Fan power(KW) | Motor Power(KW) | Production(kg⁄h) |

1680×1200×1550 | 18 | 0.05 | 0.75 | 30-40 |